In today’s high-stakes industrial environment, manufacturers can’t afford field service failures. Every delay, error, or repeat visit can damage customer trust, increase costs, and jeopardize long-term revenue. Unfortunately, outdated tools like paper forms and disconnected systems still hold many field teams back.

Smart forms—especially those purpose-built for field teams—are transforming how manufacturers overcome these challenges.

In this post, we’ll break down five common field service challenges manufacturers face—and how smart forms can help solve them, preventing costly missteps.

📊 Want the quick version? Check out our infographic for a visual breakdown of all five challenges—and how Youreka helps fix them.

1. Inaccurate or Incomplete Data Capture

The challenge: Paper forms and static PDFs miss the mark—especially in high-pressure or offline environments. Incomplete fields, illegible handwriting, and lost attachments don’t just slow you down—they break your data pipeline. Bad field data leads to delays, rework, and failed audits. Worse, it makes AI useless. You can’t generate predictions, trends, or preventive actions without clean, structured inputs.

The fix: Smart forms capture every required field with built-in validation, conditional logic, and offline functionality. Even without a connection, techs can complete forms that sync automatically later. That means accurate, complete, and consistent data—every time.

But the true value goes beyond just accuracy. Clean, structured, and complete field data is the foundation for successful AI and machine learning applications. Whether you’re aiming to predict equipment failures, optimize technician routes, or identify service trends, your AI models are only as good as the data you feed them. Smart forms turn messy field data into AI-ready insights.

2. Low First-Time Fix Rates

The challenge: Technicians often arrive on-site without the full picture—lacking historical context, access to tribal knowledge, or step-by-step instructions for servicing highly specialized equipment. This is especially problematic as experienced workers retire, taking decades of institutional knowledge with them. The cost? Lower first-time fix rates, frustrated customers, and wasted hours in the field. Every repeat trip erodes profit and trust.

The fix: Smart forms equipped with guided workflows, dynamic checklists, and embedded equipment history enable technicians to perform tasks correctly the first time—even if they’re new to the job or working on unfamiliar assets. These forms act like a digital playbook, delivering standardized procedures and interactive decision trees that adapt to real-time conditions.

In many cases, this approach helps new hires upskill faster than traditional job shadowing, accelerating time to productivity and reducing reliance on hard-to-scale training methods. When knowledge is digitized and deployed consistently, organizations retain expertise long after senior workers retire.

3. Inconsistent Compliance and Safety Documentation

The challenge: Manual documentation practices—whether paper-based or loosely structured—make it difficult to prove compliance, enforce safety protocols, or trace actions during a service audit. In regulated industries, this lack of traceability can lead to costly penalties, operational disruptions, and reputational damage.

The fix: Smart forms bring structure, consistency, and accountability to every step of the compliance process. Features like automated time stamps, photo evidence, GPS tracking, and digital signatures ensure that critical safety checks and regulatory requirements are thoroughly documented—without adding administrative overhead to field teams.

By digitizing these processes, manufacturers can easily generate audit-ready reports and ensure technicians follow the correct procedures every time. For industries subject to OSHA, ISO, or FDA regulations, having a smart documentation trail isn’t just smart—it’s essential.

4. Disconnected Field and Back Office Systems

The challenge: Field teams often work in isolation, leading to delayed updates, redundant tasks, and poor visibility across the organization.

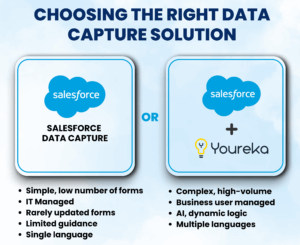

The fix: Smart forms that integrate directly with platforms like Salesforce Field Service allow field data to sync seamlessly with back-office systems. This enables real-time updates, automated follow-ups, and visibility across departments.

5. Technician Onboarding and Enablement

The challenge: Training new field technicians is costly and time-consuming, especially when processes aren’t standardized.

The fix: Smart forms function like a digital playbook—embedding step-by-step instructions, reference media, and decision logic right into the form. This helps new hires ramp faster and ensures consistency across the entire workforce.

Closing Thoughts

Why Smart Forms Are a Must-Have for Modern Manufacturing Field Teams

Manufacturers that rely on outdated or disconnected tools in the field face more than inefficiency—they risk repeat visits, safety gaps, and lost revenue.

Smart forms built for field service teams solve this at the source. They capture the right data, guide technicians through every step, and keep work moving—even without internet. With Youreka, manufacturers get field-ready tools that work seamlessly offline, online, and inside Salesforce.

The result? Smarter data, faster fixes, and a confident, connected workforce—ready to deliver exceptional service wherever the job takes them.

👉 Explore how leading manufacturers like Weber, Diversey, and Flexco use Youreka to modernize field service. Visit our manufacturing solutions page →HERE